Carbon fiber wind blades are gradually replacing full glass fiber blades to adapt to the development of greater output power of wind energy.

Carbon fiber wind blades increase strength while reducing weight, allowing these larger turbines to spin at lower wind speeds.

But carbon fiber is conductive, making it easier to be struck by lightning, but it has not enough conductivity to draw energy out of the blades. This requires additional protection to avoid catastrophic failures caused by lightning strikes.

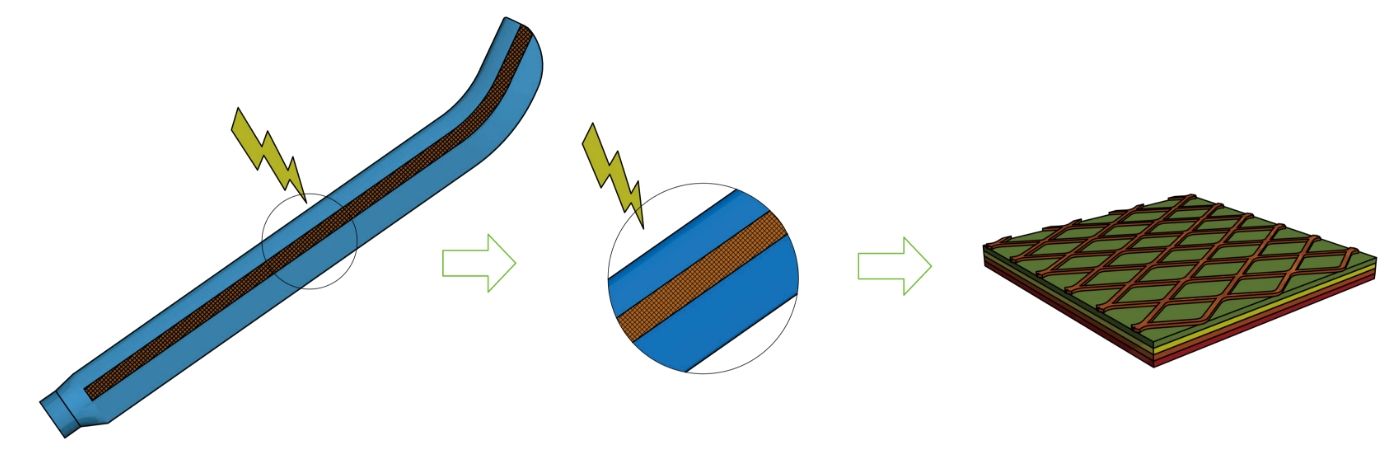

Micro expanded metal (copper or aluminum expanded metal foil) has excellent electrical conductivity. Insert the aluminum/copper expanded metal into composite material and form the material into blades to supply a lightweight shielding solution to wind energy. Besides, it is one of the ideal materials for electromagnetic compatibility of composite material.

When struck by lightning, it can play a critical electrical conductivity to effectively dissipate the destruction of lightning strike, protect the carbon fiber layer and prolong the service life.

| Material | Copper |

|---|---|

| Thickness | 0.1 mm |

| Strand Width | 0.4 mm |

| SWD | 1.47–1.752 mm |

| LWD | 3.157 mm ± 5% |

| Width | 930 mm |

| Length | ≥ 80 m |

| Overall Thickness | 0.33 mm ± 10% |

| Weight | 390 g/m2 |

| Open Area | 55% |

| Material | Copper |

|---|---|

| Thickness | 0.26–0.3 mm |

| Strand Width | 0.33 mm |

| SWD | 1.27–1.55 mm |

| LWD | 3.157 mm ± 5% |

| Width | 630 mm |

| Length | ≥ 100m |

| Overall Thickness | 0.254 mm ± 10% |

| Weight | 815 g/m2 ± 10% |

| Open Area | 64% |

| Material | Aluminum |

|---|---|

| Thickness | 0.1 mm |

| Strand Width | 0.3 mm |

| SWD | 1.2 mm |

| LWD | 2.0 mm |

| Width | 914 mm |

| Length | ≥ 100m |

| Overall Thickness | 0.15 mm ± 10% |

| Weight | 136 g/m2 ± 10% |

| Product Code | Weight (g/m2) | Material | LWD (mm) | Overall Thickness (mm) | Open Area | Length (m) |

|---|---|---|---|---|---|---|

| YWSAL-49 | 49 | Aluminum 1060 | 2.0 | 0.10 | 64% | 80–300 |

| YWSAL-78 | 78 | Aluminum 1060 | 2.0 | 0.15 | 68% | 80–300 |

| YWSAL-136 | 136 | Aluminum 1060 | 2.0 | 0.15 | 63% | 80–300 |

| YWSAL-36 | 36 | Aluminum 1060 | 2.0 | 0.04 | 64% | 80–300 |

| YWSCU-78 | 78 | Pure Copper | 2.5 | 0.10 | 85% | 80–300 |

| YWSCU-107 | 107 | Pure Copper | 2.5 | 0.13 | 78% | 80–300 |

| YWSCU-140 | 140 | Pure Copper | 3.2 | 0.13 | 77% | 80–300 |

| YWSCU-195 | 195 | Pure Copper | 2.5 | 0.13 | 70% | 80–300 |

| YWSCU-390 | 390 | Pure Copper | 3.2 | 0.33 | 55% | 80–300 |

| YWSCU-420 | 420 | Pure Copper | 3.2 | 0.33 | 53% | 80–300 |

| YWSCU-815 | 815 | Pure Copper | 3.2 | 0.25 | 64% | 80–300 |

| YWSCU-78F | 78 | Pure Copper | 2.5 | 0.05 | 85% | 80–300 |

| YWSCU-107F | 107 | Pure Copper | 2.5 | 0.05 | 78% | 80–300 |

| YWSCU-140F | 140 | Pure Copper | 3.2 | 0.08 | 77% | 80–300 |

| YWSCU-195F | 195 | Pure Copper | 2.5 | 0.08 | 70% | 80–300 |

The micro expansion mesh is widely used in the wind turbine blade manufacturing, it can also be installed on the aircraft, turbine cabin cover of wind power plants, as well as on high-altitude electrical appliances and machines to prevent lightning attacks, but also can provide a certain shielding effect.